MAYUCA®

MAYUCA® Protein Coating:

Patented technology created from the research on spinning technology of cashmere

What is silk

Silk is a natural material made by grinding threads from the cocoons of silk moths (larvae). It has a long history, and it is said that silk fabrics began to be made in China about 4,000 years ago. It has a unique luster and supple texture, and has long been loved by noble people. In addition to the graceful appearance and texture, also an excellent material for practical use as clothing. Because it has excellent moisture absorption and desorption, breathability, and heat retention, it has the advantage of being cool in summer and warm in winter, gentle on bare skin and less likely to cause rashes and contact dermatitis.[1]. In recent years, it has become clear that the silk component is close to the components that make up human skin and can be expected to have useful effects. Not only as a fiber material, but also utilized in a wide range of fields such as cosmetics, pharmaceuticals, and health foods.

Filament and Spun Silk

When you think of silk yarn, many of you may recall the scenes of old silk mills, where fine fibers are unraveled from many cocoons and reeled as they were being pulled out. This is the process of making filament silk, which can be as long as 1,500 meter. Filament silk is the only long fiber (filament) in natural yarn. Refining process, which removes the film called sericin covering the filament, gives it its unique luster and gloss.

In addition to filament silk, there is a type called spun silk (kenboshi), made by spinning. A silk thread made from short fibers that are taken out of a cocoon into a cotton-like shape, spun finely and twisted into a single thread. Compared to filament silk, it is bulky and has a soft texture. Spun and twisted, made in the same process as cashmere spinning, so is a field where our accumulated knowledge can be directly utilized.

Toyoboshi is focusing on production technology for both filament and spun silk. In addition, with an eye on the future of the industry, we are actively participating in research on new silkworm species, and are developing species that produce threads of various fineness.

Processing using natural materials

Silk is popular as clothing, but its delicate nature makes it difficult to wash and vulnerable to friction. In recent years, various types of washable silk have become available on the market. Basically, it is processed to increase resistance to moisture and friction by adding some material or chemical, and most of them are coated with resin.

Since synthetic resin is a plastic material, silk's features such as texture and hygroscopicity may be impaired, and the use of plastic is not very desirable from the viewpoint of environmental protection. The MAYUCA® coating material is a result of trial-and-error process of finding high-quality proteins suitable for silk processing. They are natural materials, of course, harmless to the human body and safe materials that are also recognized as quasi-drugs.

Patented technology developed based on cashmere processing

MAYUCA® is a patented protein coating technology developed by Toyoboshi engineers. So how did that technology come about?

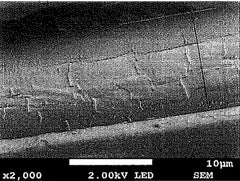

The origin lies in our knowledge and experience in spinning cashmere, responsible for improving the quality of cashmere. Cashmere raw wool is collected from cashmere goats that are raised outdoors, so it is possible to see minute scratches and discolorations caused by wind, snow and sunlight. In the dyeing process, for example, these small scratches can affect color irregularity, color development, and colorfastness (stability), and one of the challenges has been how to improve the yarn surface while maintaining the quality of the raw wool. Our in-house research department, which has been involved in this work for many years, has accumulated a variety of know-how, including detailed data on materials, permeability, possible chemical reactions, and timing of application. Based on thiese, we were able to establish a sophisticated technology to coat the silk surface with protein.

The key is adding "scale" similar to cashmere

In addition to coating technology, MAYUCA® has further ingenuity unique to Toyoboshi.

A function similar to the cashmere scale (scale-shaped cuticle) has been added.

Animal hair such as wool and cashmere absorbs and desorbs moisture by opening and closing the scale, but MAYUCA® with a pseudo scale has also evolved into a breathing fiber.

The fine protrusions of fibers that silk does not have are added to create bulges in the threads, giving a fluffy texture. By using hydrophobic hard protein as the coating material that composes the pseudo scale and applying the technology to reinforce the inside of the thread, the elasticity of the fiber is increased and the thread has kickback property (elastic recovery property). I am.

MAYUCA® protein coating is a patented technology realized only by Toyoboshi of cashmere spinning.

MAYUCA is a registered trademark of Toyoboshi Industries.

[1]Allergic Reaction may occur depending on the skin sensitivity. Should you observe any abnormalities on your skin, discontinue use and consult a doctor if necessary.